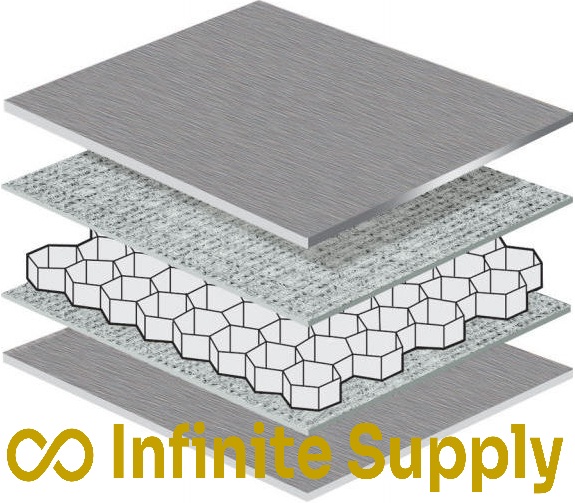

Hybrid & Reinforced Core Materials

Hybrid & reinforced core materials combine low weight, high strength, and long-term durability. Constructed from multiple cores or reinforcements—such as fiberglass, carbon fiber, or metal—these materials offer enhanced versatility and performance. Ideal for complex, high-performance structural applications.

Specifications

Density: 50–600 kg/m³ (depending on core and reinforcement type)

Compressive Strength: Up to 10 MPa

Tensile Strength: Up to 150 MPa (reinforcement-dependent)

Operating Temperature: Up to +100 °C or higher (material-dependent)

Chemical Resistance: Varies with chosen components

Compressive Strength: Up to 10 MPa

Tensile Strength: Up to 150 MPa (reinforcement-dependent)

Operating Temperature: Up to +100 °C or higher (material-dependent)

Chemical Resistance: Varies with chosen components

Advantages

Enhanced Mechanical Performance: Engineered for high-load-bearing structures.

Low Weight: Composite core structure minimizes overall mass.

Customizable Design: Suited to intricate geometries and specialized engineering requirements.

Environmental Durability: Component-specific resistance to moisture, chemicals, and temperature fluctuations.

Versatile Applications: Suitable for both structural support and aesthetic finishes.

Low Weight: Composite core structure minimizes overall mass.

Customizable Design: Suited to intricate geometries and specialized engineering requirements.

Environmental Durability: Component-specific resistance to moisture, chemicals, and temperature fluctuations.

Versatile Applications: Suitable for both structural support and aesthetic finishes.

Applications

Aerospace & Space: Lightweight, high-load panels and components.

Marine Industry: Reinforced hull and deck cores for boats and yachts.

Automotive: Lightweight composite chassis parts and structural elements.

Construction: Reinforced panels and architectural elements designed for longevity.

Wind Energy: High-strength cores for wind-turbine blade structures.

Marine Industry: Reinforced hull and deck cores for boats and yachts.

Automotive: Lightweight composite chassis parts and structural elements.

Construction: Reinforced panels and architectural elements designed for longevity.

Wind Energy: High-strength cores for wind-turbine blade structures.