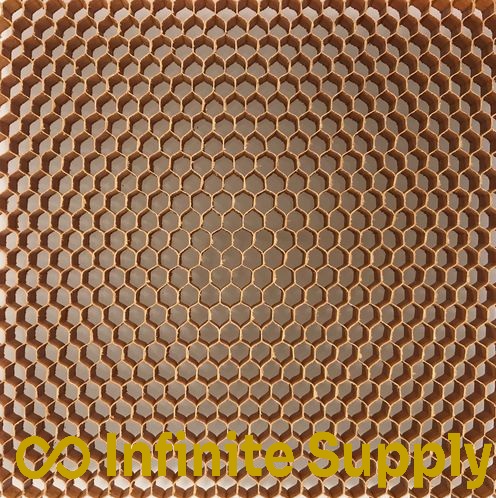

Honeycomb core materials

Lightweight yet exceptionally durable structural substrates featuring a hexagonal cell structure. They deliver high compressive and shear strength and an outstanding strength-to-weight ratio, making them indispensable in high-performance constructions. These cores also offer excellent energy absorption and versatility—key attributes for lightness, durability, and longevity across diverse industries.

Specifications

Material Options: Aluminum, aramid paper (Nomex), thermoplastics, carbon fiber, and more

Density Range: 20–200 kg/m³ (depending on material)

Cell Size: 3–30 mm (customizable to project needs)

Temperature Resistance: –50 °C to +200 °C (material-dependent)

Compressive Strength: Up to 3 MPa

Density Range: 20–200 kg/m³ (depending on material)

Cell Size: 3–30 mm (customizable to project needs)

Temperature Resistance: –50 °C to +200 °C (material-dependent)

Compressive Strength: Up to 3 MPa

Advantages

Superior Strength-to-Weight Ratio: Enables ultra-light yet robust structural panels.

High Compressive & Shear Strength: Ideal for load-bearing applications.

Excellent Energy Absorption: Dampens impacts and vibrations effectively.

Material Versatility & Customizability: Available in multiple substrates and cell sizes.

Corrosion & Temperature Resistance: Performs reliably in harsh environmental conditions.

Applications

Aerospace & Space: Aircraft panels, wing and fuselage core structures.

Transportation: Automotive door and floor panels, rail interior assemblies.

Construction: High-strength façade panels, wall and ceiling sandwich panels.

Marine Industry: Lightweight hull and deck structures for boats and yachts.

Energy Sector: Wind-turbine blade cores and insulated composite elements.