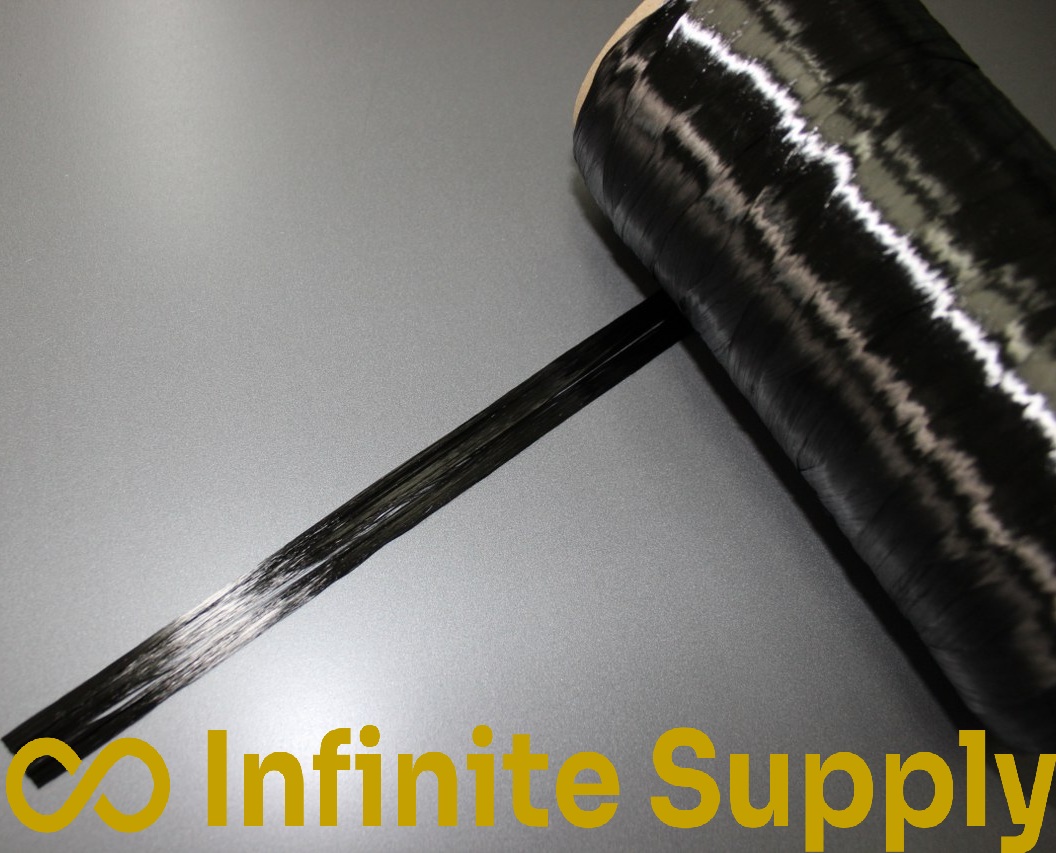

24K Carbon Tow

Our 24K carbon fiber tow delivers exceptional filament density, strength, and reliability—ideal for large-scale structures and demanding industrial applications. It’s the premium choice for aerospace, motorsports, and any sector where mechanical performance and longevity are critical.

Specifications

24K Tow: Contains 24,000 individual carbon filaments per bundle for maximum density and superior mechanical performance.

Straight Tow: A simple, linear structure that’s easy to handle and adaptable to diverse manufacturing processes.

Width Options: Offered in multiple widths to meet your exact project specifications.

Straight Tow: A simple, linear structure that’s easy to handle and adaptable to diverse manufacturing processes.

Width Options: Offered in multiple widths to meet your exact project specifications.

Advantages

High Load Capacity: Designed for heavy-duty applications and continuous use under stress.

Maximum Density: Provides outstanding rigidity and mechanical stability, even in complex, high-intensity environments.

Versatile Formability: The straight-tow format adapts readily to various shapes and structural designs.

Cost Efficiency: Higher filament density means less material is required to achieve top-tier performance.

Dimensional Stability: Dense filament architecture maintains integrity under heavy loads and variable temperatures.

Longevity: Carbon fiber’s inherent corrosion and abrasion resistance ensure extended service life—crucial for industrial and construction needs.

Maximum Density: Provides outstanding rigidity and mechanical stability, even in complex, high-intensity environments.

Versatile Formability: The straight-tow format adapts readily to various shapes and structural designs.

Cost Efficiency: Higher filament density means less material is required to achieve top-tier performance.

Dimensional Stability: Dense filament architecture maintains integrity under heavy loads and variable temperatures.

Longevity: Carbon fiber’s inherent corrosion and abrasion resistance ensure extended service life—crucial for industrial and construction needs.

Applications

Industrial & Construction: Load-bearing elements such as bridges, platforms, and large-scale structural components.

Aerospace & Motorsports: High-stress parts including aircraft wings, chassis elements, and structural panels for performance vehicles.

Robotics & Drones: Lightweight yet robust material for precision-moving components.

Wind Energy: Composite rotor blades and hub mechanisms requiring maximum strength at minimal weight.

Marine Vessels: Large structural assemblies for yachts, patrol boats, and other craft operating in harsh marine environments.

Aerospace & Motorsports: High-stress parts including aircraft wings, chassis elements, and structural panels for performance vehicles.

Robotics & Drones: Lightweight yet robust material for precision-moving components.

Wind Energy: Composite rotor blades and hub mechanisms requiring maximum strength at minimal weight.

Marine Vessels: Large structural assemblies for yachts, patrol boats, and other craft operating in harsh marine environments.